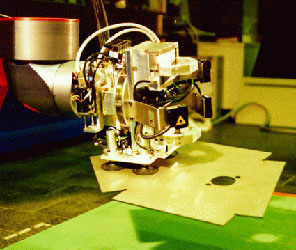

A cooperative robot with visual and tactile sensing:

In collaboration with the Center for Integrated Production Systems (ZIP), we studied how industrial processes can be automatised. Our aim was to support flexible function allocation between man and machine. In collaboration with the Institute of Working Psychology, we have developped a flexible control structure. The modular and object-oriented controller, based on Oberon (grandson of PASCAL), is specially designed to support sensor control. A graphical and configurable user-interface has been realised for programming the robot. The concept is applied to a robot which handles sheet at a press brake. For this application, a special sensor-guided, compliant gripper has been designed. The robot system has been successfully tested and is at a demonstration level.

You can form your bunch of parcels and the robot sorts the parcels:

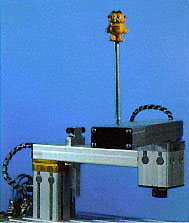

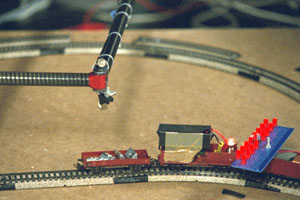

The balancing act of an inverted pendulum with a robotic manipulator is a classical benchmark for testing modern control strategies in conjunction with fast sensor guided movements. From the control design perspective it presents a challenging and difficult problem as the system is open-loop instable and includes nonlinear effects in the actuators, such as friction, backlash and elasticity. In addition, the necessity of a sensor system that can measure the inclination angles of the pendulum contributes to the complexity of the balancing problem.

The pendulum is projected onto the xz- and yz-plane of the inertial coordinate system. These projections are treated independently from each other and are controlled individually by a state-space controller in the x- and y-axis, respectively. The nonlinearities of the robot are compensated by using inverse dynamics and inverse kinematics.

A specially developed sensor system allows the contactless measurement of the inclination angles of the pendulum. This system consists of a small magnet, placed at the bottom of the pendulum, and Hall-effect sensors placed inside the end effector.

Download a QuickTime Movie (6.2 MByte)

Download a AVI Movie (4.4 MByte)

Our famous world-champion in ping-pong playing:

Scheme of the heavy duty robot Robotrac and one of the hydraulic legs in the lab:

In this project, algorithms were designed and simulated for computing fast and accurately the joint positions of an arbitrary (nonredundant) manipulator corresponding to a given pose of the end-effector. Classical geometrical methods were completed by numerical and neural network methods.

One of the best ways to learn how human beings control the hand motion is the constructive way: by trying to implement the human control on a robot. In this project, we used techniques from robotics to model the human behaviour. We implemented also biological models in order to bring useful human-like behaviours to robotics.

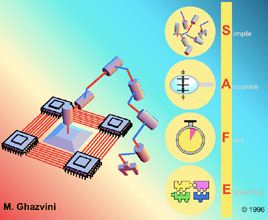

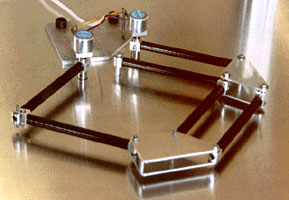

The advantages of fully parallel manipulators over serial ones are well known: the parallel mechanical structure is more rigid than a serial one, and the motors can be placed at the basis of the arms. Thus very light limbs can be used and high velocity and acceleration can be attained. This high dynamics and the large dynamic coupling between the axis however makes a nonlinear control necessary. These nonlinear control strategies must be realisable using standard hardware and fulfill the typical industrial requirements of simplicity and efficiency.

Our work consisted in selecting and testing methods for learning and compensating the (nonlinear) dynamics. Experiments were performed on a 2 dof planar manipulator dedicated to pick-and-place, as well as on the 6 dof parallel manipulator Hexaglide, that is used as a high-speed milling machine.

A simple adaptive controller, realising the steepest descent of the tracking error function, was selected as the best algorithm for learning and compensating the dynamics in arbitrary trajectories. It was shown that this controller is stable and robust to noise, enables identification of the friction and results in better control performance than when the parameters of the dynamic equations are measured.

Institute of Robotics Homepage

![]() Dec 1999, M. Honegger

Dec 1999, M. Honegger